WIZinspect - Turnkey Inspection Solution

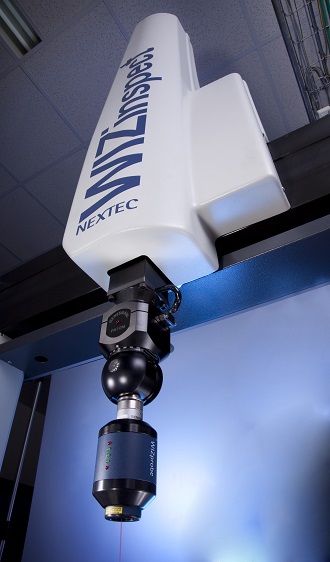

Non-contact sensors WIZprobe™ and WIZpen™ have have full integration with CMM, a state-of-the-art 4 axis motion controller, Renishaw motorized head equipment and rotary stage.

Nextec allows inspection of parts two to three times faster than standard CMM.

Together, the specialized optics and adaptive control enable WIZinspect systems to measure components with virtually any geometry, material and surface characteristics within microns.

It is also available as a standalone product with customized software packages for integration into any process control.

Also available are Wizblade, a system designed specifically for aerospace jet engine blades as well as industrial turbine, marine and compressor blades in production and MRO environments; and the Wizinspect, a turnkey, production floor inspection system for direct integration with robots and conveyors.

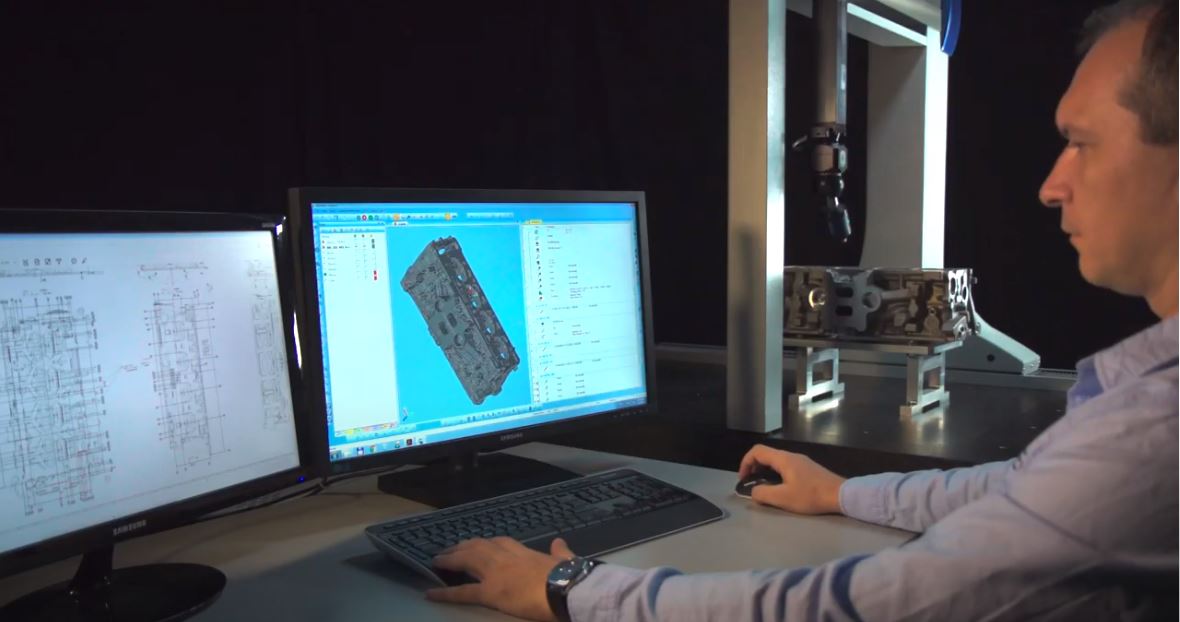

- CAD model and tolerance input

- CAD based program preparation using high level soft keys

- A variety of part alignment functions and scenarios

- Data collection from a predefined path

- Automatic surface tracking capability

- GD&T analysis

- Flexible structure of graphical and text reports using default or customized templates

- Creation of geometric elements from the scanned data and export in CAD format

- Adjustable and user friendly interface

- Users authorization control – optional levels of Administrator / Operator mode

Performance Specifications

Maximum scanning speed: 50 mm/sec.

Total system accuracy: ± 7 µm WIZprobe™

Total system accuracy: ± 5 µm WIZpen™

Note: System accuracy verification is performed according to ISO 10360-8 International Standard for non-contact CMMs

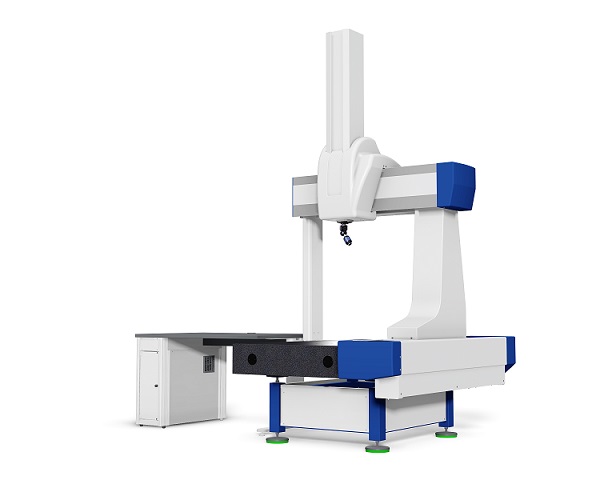

System Major Components

- Top precision CMM platform including PH10M motorized indexing head

- Non-contact optical scanning probes – Laser or White light family of probes

- 4 axis motion controller

- WIZinspect application software

- Optional top precision rotary table

Non-Contact Sensor

Laser or White light family of probes. Combines vision and laser technologies with patented optics and image processing.

CMM platform

A variety of different CMM (Coordinate Measuring Machine) platform models and sizes.

NEXTEC software – Hawk

Nextec’s Hawk software is a user-friendly and flexible solution for advanced usage – any required special function or calculation can be easily added by user and to be used in the future in other inspection programs.

Motion controller

High Reliability and Life Cycle. High motion precision. Multi-sensor support. 4 axis, 3D Tracking Capability

Rotary stage

The rotary table is used as a 4th axis for fast and efficient inspections of parts. The rotary table significantly reduces the inspection cycle time by eliminating the usage of multiple tip orientations and safety moves.